What makes a practical and efficient biosolids / sludge dryer?

Watch Alex Jr. present “What Makes Biosolids Dryers Practical & Efficient?” at the at the Mid-Atlantic Biosolids Association’s 2025 Summer Symposium, recorded July 9th, 2025.

What biosolids / sludge dryers do is remove the water content from your sludge. This reduces the sludge weight, which improves sludge disposal costs. Additionally, removing water improves the stability, handling, and even compliance of your sludge.

But most sludge dryers are too expensive for most wastewater treatment plants. Why?

They require lots of additional equipment, like boilers and furnaces, heat exchangers, dust separators and collection equipment, etc.

But it’s not just the cost of the equipment - you also need a large facility to house all of that equipment.

These capital expenditures (CAPEX) alone - the two upfront costs for the equipment and the facility - are usually enough to scare most wastewater treatment plants away from adopting sludge drying systems…

But WWTPs also need to consider the ongoing operational expenditures (OPEX) too:

Each additional piece of equipment that you have as part of an overall thermal drying system has maintenance and downtime considerations.

Most notably, thermal drying systems boil the water in the sludge into steam, which is really energy-intensive and energy-inefficient!

Heating 1 kg of water from 0 to 99°C consumes 414 kJ. Boiling water to steam at 100°C (just a 1°C difference) consumes 2260 kJ - an additional 4.5x more energy!

So the key is to avoid boiling water to steam when drying sludge. That way you end up with a much more energy-efficient dryer.

In addition to energy savings, you also create a lot fewer byproducts, like steam, heat, odor, and dust. Because you have fewer byproducts to process, you don’t need as much ancillary equipment, bringing down your upfront and ongoing costs.

In other words, by avoiding boiling water to steam, you have a practical and efficient sludge dryer for more wastewater treatment plants.

That’s what we’re doing at ELODE USA.

ELODE - the Electro Osmosis Dehydrator - doesn’t boil water to steam. Instead it electrocutes your sludge, instantly separating the water from the solids in a super fast and efficient process.

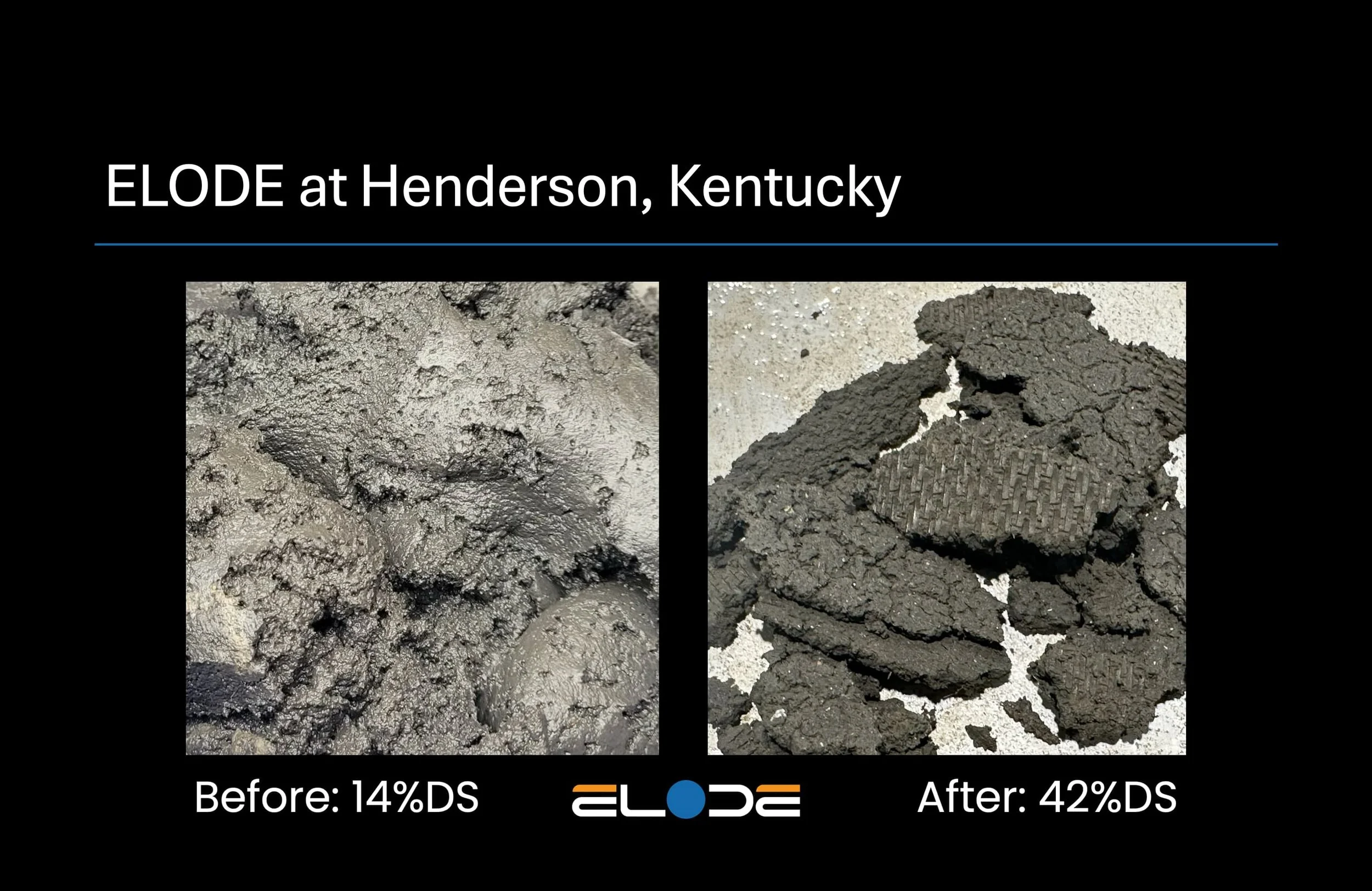

Our first ELODE installation in the US was at Henderson, Kentucky. The Water Utility there received a phone call from their local landfill: “We’re no longer going to take any more of your sludge, find another landfill.”

So they scrambled to find a solution, reaching out to various drying vendors.

Ultimately, the pioneers at Henderson Water Utility there believed the ELODE was the best for them.

They bought the biggest unit we sell (a 3-meter ELODE), which is about the size of a minivan.

Minor duct work that helps vent some of the vapors created during operation.

A water tank, pump, and drain clean some of the components during operation.

An air compressor supplies the ELODE pneumatic controls.

Conveyors bring dewatered sludge cake into the ELODE, as well as carry the ELODE-dried sludge cake out to the dumpster.

How does ELODE work?

Feed dewatered sludge into the ELODE - sludge coming out of your belt press, screw press, fan press, filter press, centrifuge, etc.

The dewatered sludge then rolls into the ELODE Dehydration Zone, where the electro osmosis (aka. electro dewatering) occurs. In the Dehydration Zone, you can see the water dripping out of the solids, through the belt filter and onto a drain pan. Remember, that’s water you don’t need to boil to steam, which is why ELODE is able to get away with such a small footprint and not require a lot of accessory equipment.

Dried sludge exits the ELODE machine, dropping onto a conveyor.

The whole process is continuous and only takes 3 minutes end to end - a minute for each step.

Operators just need to press the auto-start button and within 5 minutes, ELODE is already drying and discharging their sludge.

On the other hand, thermal dryers need hours to heat up, then hours to dry and discharge the sludge, and then hours to cool down at the end of the day. And their footprint? It would probably take up the entire building compared to our ELODE installation at Henderson, Kentucky.

In Henderson’s case, sludge cake enters the ELODE around 14% dry solids. It then exits ELODE, onto a conveyor, and into a dumpster - by the time it hits the dumpster, it reaches around 42%DS. That translates to a 67% weight reduction - the end weight is reduced down to 1/3 of its original weight!

So what does Henderson think?

“We are saving so much money with this machine.”

— Bart Boles, General Manager

“It really does reduce our solids by 60% in 3 minutes. This technology could be a game-changer for our industry.”

— Josh Thompson, Superintendent

“We’re glad we bought the ELODE machine. It is even more valuable because it gives us goodwill with the Daviess County landfill. They love our sludge.

It is a slam dunk decision.”

— Kevin Roberts, Director of Operations

Now there is a drawback of ELODE: it can’t dry up to 90% solids (but thermal dryers like the Evaporative Dryer [EVD] can).

For municipal wastewater biosolids, ELODE drying performance seems to be less effective after 50%DS because at that point, the sludge starts to act like an insulator rather than a conductor, which isn’t conducive to a process that requires electricity to flow.

BUT you need to consider the diminishing returns of sludge weight reduction vs. % dry solids achieved.

If you’re going from 15% solids to 50%DS, you’re reducing the weight of your biosolids by 70%!

If you’re going to 90% solids, you’re only going to reduce the weight of your biosolids by an additional 13%.

Is that additional 13% weight reduction worth having to boil sludge water into steam? Because then you’ll need all that extra equipment to purchase, maintain, house, and waste energy on.

That being said, ELODE and thermal dryers can be complementary as well - you can always feed ELODE-dried sludge cake into a thermal dryer to achieve what % solids you want in the most efficient way possible. There’s even an academic study that confirms the benefits of using electro osmosis prior to thermal drying to maximize drying efficiency.

So what makes a practical and efficient sludge dryer?

It’s one that doesn’t have to boil water to steam, like ELODE!

ELODE uses the least amount of energy possible - only 1/3 compared to conventional thermal dryers.

ELODE also creates way fewer byproducts, like steam, heat, and odor. Notably, there’s no dust generated during electro osmosis, meaning that you don’t need dust separation and collection equipment, nor do you have to worry about the explosion hazards associated with dust.

ELODE machines are also stock units with small footprints because they don’t require many accessories like other thermal dryers.

As a result of bypassing the need to boil water to steam, ELODE is a practical and efficient sludge dryer, which is more feasible for more wastewater treatment plants in the US to use.

Interested in ELODE and other practical and efficient sludge dryers? Contact us today!